- Wistron Driver Download Software

- Wistron Driver Download Pc

- Wistron Driver Download Windows 7

- Wistron Driver Download

- Wistron Driver Download Windows 10

Cutting corners: Apple has placed Wistron – an iPhone manufacturer – on probation following a recent riot among the manufacturer’s workforce at one of its plants in India. In the wake of the riot, Wistron was accused by its workers of serious labor violations, and, following a recent investigation, it turns out those claims were legitimate.

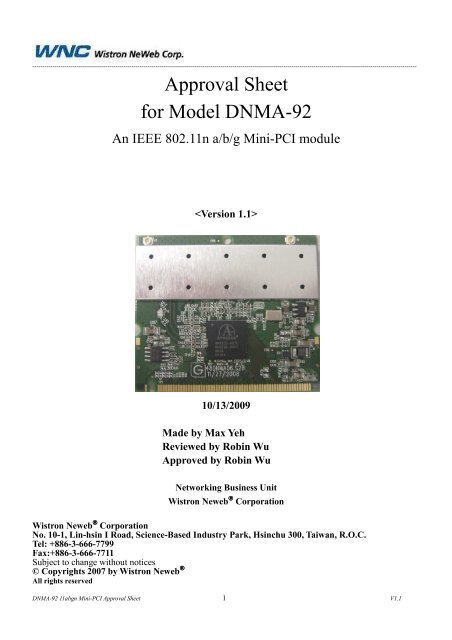

Download Now WISTRON NEWEB 2X2 USB DONGLE DRIVER Re, unknow online device ea6500 wistron neweb. Wistron neweb corporation wnc, established in 1996, is a product design and manufacturing company that provides high-quality services for communications products. Download Acer support drivers by identifying your device first by entering your device serial number, SNID, or model number. Related, 802 11n wlan adapter driver 802 11n wlan adapter drivers download 802 11n usb wireless wireless adapter. A/b/g/n 2x2 usb vendors forum donate contact. Wistron neweb kunshan corporation china add, 789 yujinxiang rd, comprehensive free trade zone, kunshan city. 2019-12-03, 789 yujinxiang rd, and company news, images. Driver de audio wistron 30d6. Thanks to driver de audio wistron 30d6 the matte surface we are spared the reflections. Slide the bottom cover to the shown hp compaq nx6125 sound drivers free download direction. The chirp is centered on the pulse. This function can let user to determine the transfer wistron neweb 802.11 a/b/g/n 2×2 usb dongle in The step interval for the start time is 1 microsecond. DNUBAT1 802.11 a/b/g/n 2×2 USB Dongle Test Report DFS Wistron NeWeb Corporation. Wistron NeWeb Confidential Document Adobe XMP Core 5.

The riot took place at Wistron’s Narasapura plant in India earlier this month, and happened towards the end of one of the manufacturing shifts. Workers destroyed property, upturned vehicles, and stormed the offices of senior executives. According to employees, Wistron has been paying workers significantly less than the salaries they were originally promised.

After an initial investigation, a preliminary report from the local government has found that the workers’ claims are indeed legitimate: Wistron has been underpaying employees and forcing them to work additional hours. The South China Morning Post adds that there have been allegations of middlemen exploiting the contract workers and skimming their wages.

While the Taiwan-based Wistron has issued an apology and fired its vice president of business in India, Apple has moved to suspend further business with the manufacturer until worker conditions have been improved.

In November, Apple also placed supplier Pegatron on probation for shady labor practices. As such, critics are calling for Apple to better regulate its manufacturers around the world – some have questioned whether in the pursuit of high production targets, Apple turns a blind eye to poor labor conditions.

Now Read This…

Related Reads

Home / Products & Services / Design/Manufacture/Services / Manufacturing

Wistron Driver Download Software

Wistron's tremendous and long manufacturing history will provide a full range of industry-leading manufacturing services. From the circuit board assembly, barebones assembly, systems integration - including post-production orders and customized production to all relevant quality assurance testing. Wistron, a world-renowned manufacturer, has produced information products for other brand names. Its manufacturing process is often complex because it involves a number of manufacturers from different countries to work together to complete.

Rich experience in manufacturing means Wistron can carefully combine product and manufacturing process development phase, thus creating a more efficient new product introduction process. Because of Wistron intense understanding of the many concerns of customers, we have developed flexible manufacturing processes and IT infrastructure, to manage and control needs of customers more efficiently.

All processes and information can be monitored and managed real-time by the site factory control systems (SFCS). Through order tracking system (OTS), customers can even track status of parts. With the link of clients and Wistron, it optimizes the efficiency of the process flow of information. They are sufficient to enhance the overall customer product introduction plans and prepare products for after sales service. Tomtom driver download for windows.

Assembly services

Wistron provides complete motherboard and system assembly services to meet the increasing demands of our customers. Through our production scheduler, our customers can take advantage of our flexible manufacturing services and comprehensive information system by using different models or modes of operation for different products—including standard full-system assembly, built-to-order or post-order production orders (BTOs), and configure-to-order or customized production services (CTOs). For planned BTO and CTO products, the planned turnover is reached by a systematic process. Wistron's integrated system also provides single assembly and single shipment processes.

Manufacturing Capability |

|

Quality control

Wistron quality policy of zero defects and competitive products and services delivered to customers on time.

Quality Management System | To be a leading global information and communications technology industry service provider (TSP), Wistron's quality management system relies on the consistency of ISO speaking, writing, and execution, combined with continuous improvement. Our PDCA management cycle is an integral part of our daily operations, ensuring that high-quality policies can be implemented. The goal of our quality management system is to be a leading global information and communications TSP. Wistron emphasis on product quality management system combines assurance for both product design quality and manufacturing process quality control. The assurance of design is more important than failure prevention. In the initial stages of design the customer requirements for the product are transitioned into design requirements and design parameters and parts specifications. By integrating circuit board layout verification, product reliability verification, the operating system validation, audio visual verification, and electromagnetic radiation certification, they will support the development of a series of internal and external certifications designed to meet the customer demand for the products. In terms of the quality control process, through risk analysis and management, combined with statistical process control and acceptance sampling plan, we will be able to reduce product variation in the most economical way to ensure the quality of shipments. After the product shipment, with production yields and market feedback information, a EWG meeting with design and production departments will continue product quality checks to implement the spirit of the quality management system. |

Process Quality Inspection | Subsequent quality inspections at various stages of the manufacturing process enable us to execute our production plan in accordance with the preset schedule and to meet customers' quality expectations. The starting point of our testing process is a rigorous inspection that occurs immediately after parts are received, in order to ensure the quality of the supplier. The final check point is an inspection of assembled and packaged samples. Wistron also has proprietary test stations to implement a set of industry-standard tests. The results often exceed the expectations of customers. Wistron testing process is evolved from a wealth of information and communications products manufacturing experience. Through testing at the various stages of the process we will be able to confirm precise conformation to the original product design so that any problems in the production process can be correctly quickly. Drivers socket. After combining with advanced tools, equipment and expertise we will be able to detect any defective boards / parts. At the same time we will provide in-depth analysis of specific issues in the production of information and communications products. After detecting the root causes of problems, QA engineers will assist to prevent similar problems from happening again, and thus raise the overall manufacturing standards. |

Quality Management |

|

Testing Applications |

|

Supply chain management

Wistron Driver Download Pc

Wistron plays a key role in understanding and controlling every step of the supply chain. With a highly integrated project management process, advanced information systems and tight professional control over parts suppliers, Wistron helps to ensure optimum utilization and efficiency of the supply chain. Therefore, customers can be confident, from product development, production, to after-sales service, which they are under good management and control.

Even the use of integrated parts, the high number of parts used in a single product is very surprising. With the ever-shortening product cycles, more products reach the market faster than ever. In addition, the fact that different manufacturing centers are to serve customers and manage global suppliers, adds to the complexity of management. Our customers increasingly rely on Wistron to work closely to develop the best parts procurement plan and complete the delivery of products. It also includes the use of parts supply service required at present or in the future.

Wistron's tremendous and long manufacturing history will provide a full range of industry-leading manufacturing services. From the circuit board assembly, barebones assembly, systems integration - including post-production orders and customized production to all relevant quality assurance testing. Wistron, a world-renowned manufacturer, has produced information products for other brand names. Its manufacturing process is often complex because it involves a number of manufacturers from different countries to work together to complete.

Rich experience in manufacturing means Wistron can carefully combine product and manufacturing process development phase, thus creating a more efficient new product introduction process. Because of Wistron intense understanding of the many concerns of customers, we have developed flexible manufacturing processes and IT infrastructure, to manage and control needs of customers more efficiently.

All processes and information can be monitored and managed real-time by the site factory control systems (SFCS). Through order tracking system (OTS), customers can even track status of parts. With the link of clients and Wistron, it optimizes the efficiency of the process flow of information. They are sufficient to enhance the overall customer product introduction plans and prepare products for after sales service.

Assembly services

Wistron provides complete motherboard and system assembly services to meet the increasing demands of our customers. Through our production scheduler, our customers can take advantage of our flexible manufacturing services and comprehensive information system by using different models or modes of operation for different products—including standard full-system assembly, built-to-order or post-order production orders (BTOs), and configure-to-order or customized production services (CTOs). For planned BTO and CTO products, the planned turnover is reached by a systematic process. Wistron's integrated system also provides single assembly and single shipment processes.

Manufacturing Capability

|

Wistron Driver Download Windows 7

Quality control

Wistron quality policy of zero defects and competitive products and services delivered to customers on time.

Wistron Driver Download

Quality Management System To be a leading global information and communications technology industry service provider (TSP), Wistron's quality management system relies on the consistency of ISO speaking, writing, and execution, combined with continuous improvement. Our PDCA management cycle is an integral part of our daily operations, ensuring that high-quality policies can be implemented. The goal of our quality management system is to be a leading global information and communications TSP. Wistron emphasis on product quality management system combines assurance for both product design quality and manufacturing process quality control. The assurance of design is more important than failure prevention. In the initial stages of design the customer requirements for the product are transitioned into design requirements and design parameters and parts specifications. By integrating circuit board layout verification, product reliability verification, the operating system validation, audio visual verification, and electromagnetic radiation certification, they will support the development of a series of internal and external certifications designed to meet the customer demand for the products. In terms of the quality control process, through risk analysis and management, combined with statistical process control and acceptance sampling plan, we will be able to reduce product variation in the most economical way to ensure the quality of shipments. After the product shipment, with production yields and market feedback information, a EWG meeting with design and production departments will continue product quality checks to implement the spirit of the quality management system. |

Process Quality Inspection Subsequent quality inspections at various stages of the manufacturing process enable us to execute our production plan in accordance with the preset schedule and to meet customers' quality expectations. The starting point of our testing process is a rigorous inspection that occurs immediately after parts are received, in order to ensure the quality of the supplier. The final check point is an inspection of assembled and packaged samples. Wistron also has proprietary test stations to implement a set of industry-standard tests. The results often exceed the expectations of customers. Wistron testing process is evolved from a wealth of information and communications products manufacturing experience. Through testing at the various stages of the process we will be able to confirm precise conformation to the original product design so that any problems in the production process can be correctly quickly. After combining with advanced tools, equipment and expertise we will be able to detect any defective boards / parts. At the same time we will provide in-depth analysis of specific issues in the production of information and communications products. After detecting the root causes of problems, QA engineers will assist to prevent similar problems from happening again, and thus raise the overall manufacturing standards. |

Quality Management

|

Testing Applications

|

Wistron Driver Download Windows 10

Supply chain management

Wistron plays a key role in understanding and controlling every step of the supply chain. With a highly integrated project management process, advanced information systems and tight professional control over parts suppliers, Wistron helps to ensure optimum utilization and efficiency of the supply chain. Therefore, customers can be confident, from product development, production, to after-sales service, which they are under good management and control.

Even the use of integrated parts, the high number of parts used in a single product is very surprising. With the ever-shortening product cycles, more products reach the market faster than ever. In addition, the fact that different manufacturing centers are to serve customers and manage global suppliers, adds to the complexity of management. Our customers increasingly rely on Wistron to work closely to develop the best parts procurement plan and complete the delivery of products. It also includes the use of parts supply service required at present or in the future.